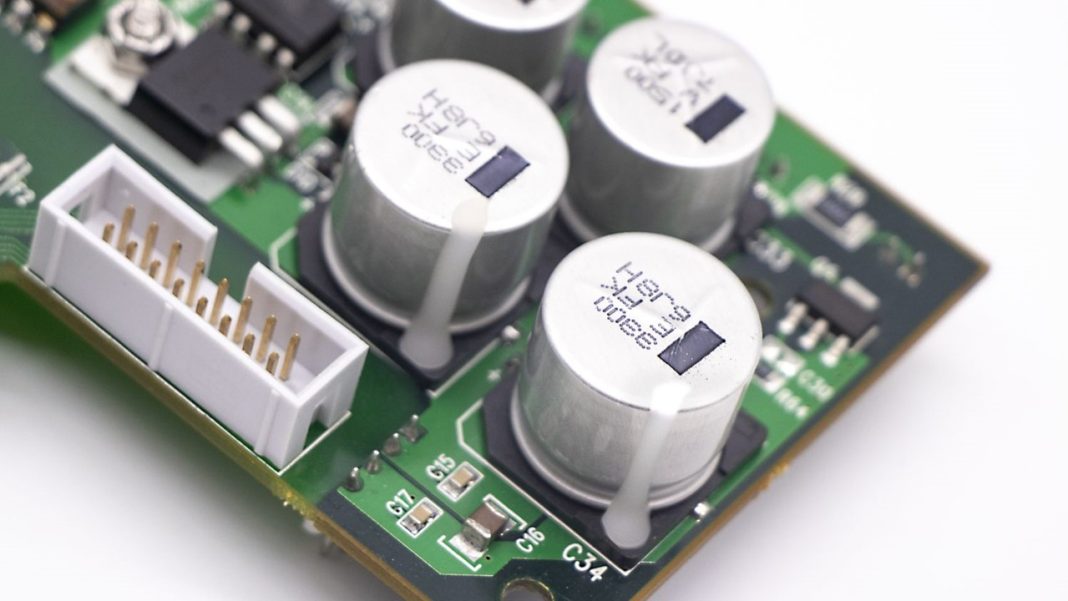

Adhesives specialist Intertronics presents a new adhesive for ruggedising and staking critical electronic components onto printed circuit boards (PCB) for the aerospace and defence sectors. Dymax 9773 combines low outgassing, dielectric stability and on-demand UV curing to address the reliability and production throughput requirements in these industries.

Dymax 9773 is a single part light curing adhesive suitable for applications in electronics assembly and optical applications. It has a unique combination of benefits which will be useful for aerospace and defence companies; their products go into high-reliability environments, which cannot be repaired once deployed, and where even small, gradual changes can become mission-ending problems.

Dymax 9773 is very low outgassing; it passes ASTM E595 with low Total Mass Loss, and is NASA MAPTIS listed. Materials which outgass even very small amounts of vapour when exposed to heat and vacuum can, over time, cloud optics, upset thermal control surfaces, or interfere with sensitive electronics – quietly degrading performance even though nothing appears visibly wrong. Meeting NASA outgassing requirements is often essential.

The adhesive satisfies MIL-STD-883 Method 5011, which shows that it remains electrically insulating, dielectrically stable, and physically intact after prolonged high-temperature exposure. The threat of ionic migration is a critical reliability risk for electronics in remote environments, so adhesives used must show stable electrical performance.

Defence manufacturers still demand extreme reliability, but they now also need to produce more, faster, and at scale. That has shifted attention toward processes and materials that maintain qualification standards while improving throughput and productivity, rather than relying on slow, labour-intensive methods.

Dymax 9773 is a single part, non-slumping adhesive which cures in seconds with UV/visible light. This represents an important upgrade on slow, multi-part epoxies or silicones and it is compatible with automated dispensing and jetting within scalable production settings.

“This adhesive was designed to fulfil a range of purposes in mission-critical aerospace, defence and optics applications,” said Matt Baseley, Head of Sales at Intertronics. “This includes shock and vibration absorption, encapsulation, ruggedisation and reinforcement of electronic components, and underfill.

“This unison of three key properties addresses a need in the market with a dedicated product for design engineers in these highly controlled sectors,” explained Baseley.

No solvents or halogens are used in Dymax 9773, and it is Restriction of Hazardous Substances (RoHS) compliant, helping manufacturers to meet Defence Environmental Protection (DEPR), Environmental Protection Agency (EPA), and any other environmental regulations that apply.

To learn how Dymax 9773 could upgrade your electronics manufacturing for satellite, aerospace or defence products, read more here or speak to an Intertronics expert today.