For highly regulated industries such as aerospace manufacturing, where components must withstand harsh conditions, thorough quality assurance testing is essential. Here, Dr. Jan Kretschmer, Senior Sales Manager at Thermo Fisher Scientific, explores how combining a range of microscopy techniques is essential to boost the quality and reliability of aerospace components.

In addition to verifying the production processes of parts, quality assurance helps to ensure that the materials used within aerospace applications are reliable and meet required standards. These include AS 9100, which is crucial for organisations that design and manufacture aviation products. Consequently, aerospace manufacturers must have a thorough understanding of the microstructural composition of different materials employed within the product development process, allowing them to alleviate any issues.

Some of the most important materials for quality assurance engineers to characterise are aluminium and nickel-based superalloys.

As the aerospace industry increasingly demands materials with enhanced strength, toughness and corrosion resistance, aluminium is an ideal choice. The high strength-to-weight ratio of aluminium alloys facilitates the production of robust, lightweight components that can help boost fuel efficiency. Furthermore, aluminium’s natural corrosion resistance can prolong the working life of components that must withstand the harsh environments and various atmospheric conditions encountered at high altitudes.

Nickel-based superalloys are also exceptionally well suited to aerospace applications such as aircraft engines due to their excellent mechanical properties even at high temperatures, as well as their resistance to corrosion, creep and oxidation.

However, the manufacturing process steps that components made using these kinds of alloys undergo can have either a detrimental or beneficial impact on the mechanical performance and conformance of the part. Additionally, the harsh temperatures and conditions that the components are subjected to can also have a negative effect on their mechanical properties. Therefore, applying a range of advanced imaging techniques — be that using the same piece of equipment or several different solutions — is necessary to ensure that these processes do not jeopardise safety and quality.

Aluminium lightweighting

A common measure to reduce weight across an aircraft’s wings, fuselage, empennage and engine casings is implementing aluminium-lithium (Al-Li) stiffened panels. To avoid hot cracking in high-strength 2000 series Al-Li and 7000 series Aluminium-Zinc-Magnesium (Al-Zn-Mg) alloys, friction stir welding (FSW) is a preferable joining technique. FSW creates a weld by stirring solid metal between adjoining plates rather than melting it, resulting in a lower processing temperature that prevents safety issues caused by cracks or porosity.

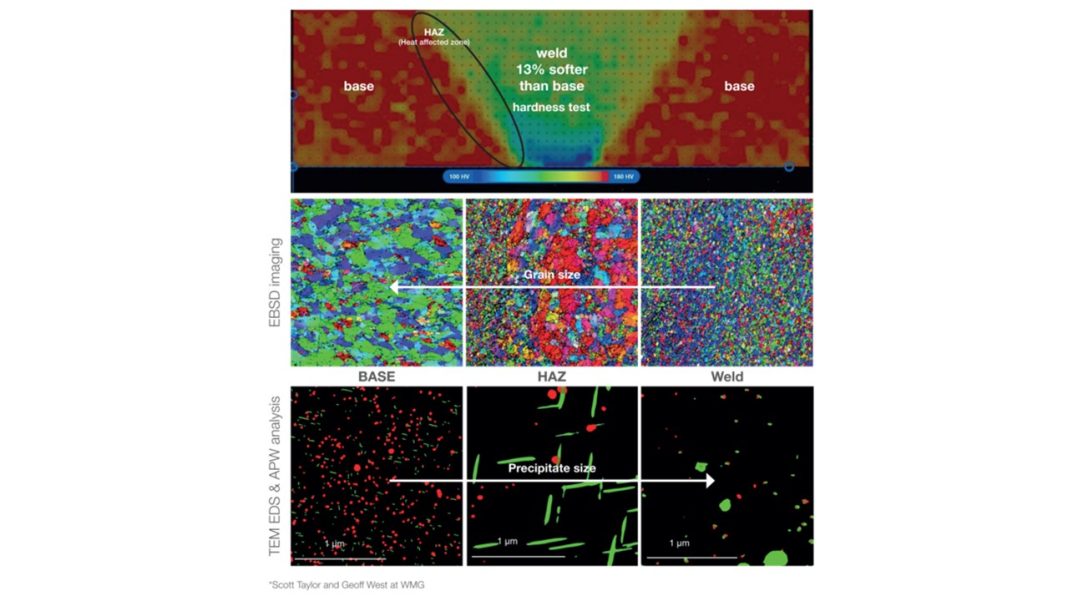

Unfortunately, the weld region of the alloys often ends up much softer and with reduced yield strength than the base metal. The nanoscale changes occurring within the stirred zone require further analysis with advanced imaging technologies. However, it is essential to combine several techniques to provide a thorough understanding of why the welding process results in a reduction of the alloy’s mechanical properties.

In this case, scanning electron microscopy (SEM) can be used to investigate the main elements and composition of intermetallic particles in the base, heat affected zone (HAZ) and weld of these alloys. However, a change in the particles is not easily linked with the decrease in strength present in the weld. Electron backscattered diffraction mapping (EBSD) allows for a deeper dive into the microscopic structure, showing the difference in grain size in the base, HAZ and weld.

Although grain refinement in the weld may contribute to improved strength, the possible loss of dislocations could have the opposite effect. Further study utilising a plasma focused ion beam (PFIB) microscope and a transmission electron microscope (TEM) helps to reveal the density of edge and screw dislocations from base to HAZ to weld.

Finally, chemical mapping by energy-dispersive X-ray spectroscopy (EDS) and particle quantification by Automated Particle Workflow (APW) help to reveal the precipitates responsible for increased strength, with this being affected during the welding process.

The impact of alloying elements on the quality of final products

While it is important to understand the impact that welding methods have on aluminium components, analysing the effect of adding alloying elements is also essential for quality assurance engineers. For example, in the case of AA2024, a widely used alloy known for its low weight and resistance to corrosion, the addition of alloying elements such as copper, magnesium or manganese leads to the formation of precipitates whose type varies based on the applied treatments. Therefore, it is crucial to comprehensively characterize raw materials during the manufacturing process, revealing the compositional and microstructural evolution of the alloy under different treatments such as aging, hardening, or annealing.

By using a solution such as the Thermo Scientific™ Apreo™ ChemiSEM, it is possible to combine four methods within one microscope — scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS), and electron backscatter diffraction (EBSD). The combination of these techniques reveals detailed alloy composition and structure essential for quality control.

SEM and EDS provide a microscale characterization with the Thermo Scientific™ ChemiSEM™ Technology, revealing the compositional data, showing the morphology and elemental makeup of intermetallic particles particularly phases rich in copper, manganese and magnesium.

EBSD is employed to map crystallographic phase, grain structure, grain orientation and morphology, enabling correlations between alloy treatment, grain size and mechanical properties. Such details can be used to optimize heat treatment parameters in order to achieve desired mechanical properties and performance. The Apreo ChemiSEM system integrates these analyses, delivering comprehensive insights into precipitates and phases formed through varied aging treatments. This combined approach is invaluable in refining aluminium alloys to meet stringent aerospace standards.

Extreme temperatures

In the case of nickel-based superalloys — which are used within aeroplane engines reaching temperatures of up to 2,000°C — ensuring that they are able to withstand these harsh conditions is essential. The Apreo ChemiSEM’s seamless integration of imaging, EDS and particle analysis offers a comprehensive approach to characterising and optimising materials for quality assurance.

The high-resolution SEM provides a clear visual overview of the material’s surface and internal structures, while the EDS allows engineers to map out the distribution of elements, such as nickel, chromium and aluminium in superalloys and to identify phase compositions critical to alloy performance. Particle analysis in the ChemiSEM uses automated software to quantify and categorise particles, such as carbides and oxides, within an alloy. This capability allows for the measurement of particle size, shape and distribution, which are key factors affecting material properties like creep resistance and corrosion. By understanding the characteristics of these particles, quality engineers can refine and improve material treatments to enhance the durability of components.

Microscopy techniques are also beneficial in characterising thermal barrier coatings (TBCs), which provide protection and insulation for aerospace components used in high-temperature applications. Combining the Apreo ChemiSEM with tools like the CleanMill Broad Ion Beam (BIB) System allows engineers to observe phase transformations and elemental distributions across TBC layers, which are essential for protecting aircraft components from high temperatures and oxidation. By integrating SEM imaging with EDS and AI-assisted analysis with Thermo Scientific™ Avizo™ 3D Pro Software, the Apreo ChemiSEM provides a complete characterisation of these coatings, revealing how elements like magnesium and zirconium behave under repeated thermal cycling. Such insights are invaluable for optimizing TBC formulations to extend component lifetimes.

The highly regulated nature of the aerospace industry means that quality engineers cannot afford to overlook potential defects or weaknesses in component parts. Combining a wide range of imaging and analysis techniques allows them to fully understand — and consequently improve — the properties of component materials such as aluminium and nickel.

Learn more about Thermo Fisher’s range of imaging solutions, here.