Modern rail systems employ a range of sensors and monitoring devices that deliver precise data on various components, from tracks to rolling stock. These systems excel at identifying issues in real-time, alerting operators to potential problems like track misalignments, wheel defects or electrical failures. Despite this, the technology often operates in silos, providing isolated data points without a comprehensive understanding of how these faults interrelate. This disjointed approach limits the ability to diagnose root causes, often resulting in reactive, rather than proactive maintenance.

Data fusion represents a significant challenge in the rail industry, particularly concerning the integration of location-based data from disparate sources. Accurate location tracking is crucial for efficient rail operations, safety and maintenance. However, the complexity of merging data from various sensors, GPS systems and other location-based technologies often leads to inconsistencies and gaps in information. This barrier hampers the ability to generate precise, real-time insights necessary for optimal decision-making.

There are companies within the industry working to address the data fusion challenge. For example, Machines with Vision is implementing advanced visual technology to integrate and enhance location-based data. By leveraging high-resolution cameras and sophisticated algorithms, they provide precise real-time maps of railway environments. This approach significantly improves the accuracy and reliability of location data, overcoming inconsistencies and gaps that typically hamper decision-making. Its solution enables a comprehensive understanding of rail operations, enhancing safety, efficiency and maintenance planning through a more integrated and accurate data fusion process.

The aerospace industry offers valuable insights into overcoming these challenges. Aircraft are equipped with advanced health monitoring systems that not only detect faults but also integrate data from multiple sources to provide a holistic view of the aircraft’s health. By employing sophisticated algorithms and machine learning, these systems can predict potential failures before they occur, enabling pre-emptive maintenance that minimises downtime and enhances safety.

For the rail industry, adopting similar integrated diagnostic systems could be transformative. By utilising big data analytics and machine learning, rail operators can aggregate and analyse data from various subsystems, uncovering patterns and correlations that would otherwise go unnoticed. This holistic view enables a more accurate identification of root causes, allowing for targeted maintenance interventions that prevent issues from escalating into costly repairs.

Digital twin technology, widely used in manufacturing, presents another opportunity for the rail industry. A digital twin is a virtual replica of a physical asset, continuously updated with real-time data. In manufacturing, this technology enables operators to simulate different scenarios, optimise processes and predict equipment failures with high accuracy. Companies such as Xi Engineering Consultants, renowned for their expertise in digital twinning, are already delivering digital twin solutions, offering trusted, data driven services that enhance operation efficiency and performance.

Implementing digital twins in rail systems could enhance fault detection and maintenance planning. For example, a digital twin of a train or track segment could simulate the impact of various stressors over time, predicting wear and tear and suggesting optimal maintenance schedules. This predictive capability allows for more strategic maintenance planning, reducing unplanned downtime and extending the lifespan of assets.

To fully realise the potential of these cross-sector technologies, the rail industry must embrace a culture of innovation and collaboration. This involves investing in platforms that integrate data from various monitoring systems and applying advanced analytics to identify patterns and predict failures. Forming partnerships with technology providers and industries that have successfully implemented advanced fault detection and maintenance planning technologies is crucial.

Additionally, equipping maintenance teams with the skills needed to interpret complex data and operate new diagnostic tools effectively is essential. Launching pilot projects to test and refine integrated fault detection systems and predictive maintenance strategies will also be key to driving this transformation.

By looking beyond traditional practices and adopting technologies from aerospace, manufacturing and other sectors, the rail industry can significantly enhance its fault detection and maintenance planning capabilities. This integration promises not only to improve operational efficiency and safety but also to reduce costs and extend the life of critical infrastructure. As the rail industry navigates this transformation, the lessons learned from other sectors will be invaluable in shaping a more resilient and responsive rail network.

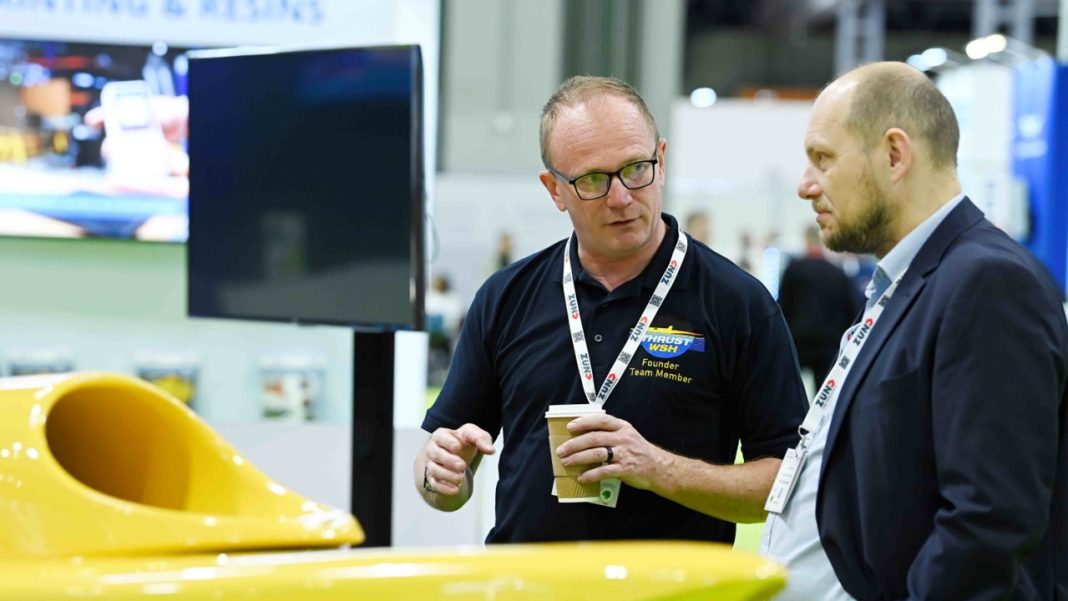

There’s no better place for the rail industry to explore innovative solutions and form valuable partnerships than at the Advanced Engineering UK trade show. This event brings together a diverse array of sectors, offering a unique opportunity to learn from advancements in aerospace, manufacturing and beyond. By attending the show at the NEC, Birmingham, on October 30 and 31, 2024, rail professionals can discover cutting-edge technologies that can revolutionise fault detection and maintenance planning.

Register your attendance today via the Advanced Engineering website here.